Efficiency and Velocity: CNC machines make production faster by automating their machining processes. They function nonstop without tiring out or enduring tiredness, furnishing around-the-clock production if necessary.

Compared to injection molding, CNC machines provide a speedier charge of pace. In contrast to injection molding, which could consider months to make a mold and ensure the machined parts are in just tolerance, CNC machining can supply objects in weeks.

The automotive industry is amongst the major sectors for CNC machining. CNC machining gives advantages at each stage on the automotive manufacturing method, from prototyping in Analysis and Growth (R&D) to creating significant portions of parts.

The applications of CNC systems in these sectors are large, from intricate customized designs for weapon bodies to a missile’s inside elements. Here are a few of the parts that are made utilizing a CNC manufacturing method:

Over the excursion, Bredikhin visited four on the Taiwanese machine tool producers whose equipment he afterwards imported, and also 1 other, As outlined by considering that-eliminated photos and posts shared to Facebook and Instagram. At 3 in the facilities, he and Yu are pictured supplying a thumbs up.

As a result of need for top precision, only CNC machining provides the required characteristics for virtually any optical interaction project. Many of the applications of CNC machining inside the optical sector are:

One of several a lot of advantages of CNC Precision Machining is its flexibility pertaining to materials compatibility. Companies can pick distinctive possibilities according to portion necessities, Every providing unique rewards.

Tolerances are important in precision CNC machining functions because they lessen production costs and turnaround moments. As critical as These are, they have to read more have A lot abilities and the perfect time to get the right way. CNC machines have an average tolerance of 0.005 inches.

The very higher level of precision wanted inside the aerospace industry will make CNC machining a suitable manufacturing approach for the sector.

There exists a good amount of a unique form of CNC machine based on the applications and industrial prerequisites. Similarly, Sometimes industrial designers and mechanical engineers are inclined to produce some machines in-household for in-dwelling prerequisites. Applying stepper motors, motor controllers and G-codes will help them to acquire custom CNC machines.

CNC technology is a cornerstone with the Power industry Considering that the nineteen seventies, enabling the production of complex and substantial-overall performance parts.

Once the aspect is manufactured utilizing the precision machine, it may be eradicated. According to the necessities, the portion could be sent for secondary procedures which include grinding or sprucing.

software package is an crucial and sizeable attribute of the CNC gadget. You will find Unique styles of program plans which can be CAD-associated software package programs and Machining operating software package. That's executed via system microprocessors.

Once the designs in CAM structure are comprehensive, it really is time to build the machine. This will usually necessitate machine tool calibration and mounting the workpiece on the machine. The machine tools used vary depending upon the workpiece substance and last item design.

Michael Oliver Then & Now!

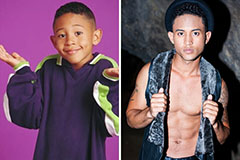

Michael Oliver Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now! Andrew McCarthy Then & Now!

Andrew McCarthy Then & Now! Sarah Michelle Gellar Then & Now!

Sarah Michelle Gellar Then & Now!